Gruenberg Ships Conveyor Oven to the Medical Industry

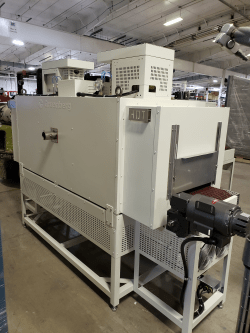

Thermal Product Solutions, a global manufacturer of thermal-processing equipment, announced the shipment of a Gruenberg conveyor oven to the medical industry.

This curing conveyor oven has a maximum temperature rating of 360ºF and an operating temperature range of 300ºF and 330ºF. The interior chamber is constructed with aluminized steel and has dimensions of 22” W x 66” L x 16” H. A heat resistant nylon conveyor belt transports product through the oven and the conveyor system includes a variable frequency drive for speed adjustments to meet processing requirements.

The oven utilizes a high volume 800 CFM vertical down airflow system to direct air down into the workspace through diffusing panels. This allows the air to flow down through the product and conveyor belt. The air then exits the workspace at the bottom and is directed into re-circulating ducts on either side of the unit. The heating system uses seamless-tubular incolloy sheathed heaters to supply energy efficient electric heat. A cooling module is located at the end of the oven module to cool the parts after processing.

“This Gruenberg conveyor oven is designed to maintain a temperature uniformity of +/-5 ºF at temperatures of 300ºF and 330ºF. In addition, to minimize swings in setpoint temperature, power controls are installed to proportion power as necessary. Our team strives to provide solutions for our customers that optimize their process and exceed their expectations.”

– Mike Schneck, Director of Engineering

Unique features of this Gruenberg Conveyor Oven include:

- Variable frequency drive for adjustable conveyor speed

- Watlow EZ Zone PM controller for fast, efficient start up

- High limit controller to prevent heating past customer’s preset limit

- Stand-alone cooling module at end of oven

- SCR power control

- Complies with NFPA 86 Class B requirements

#146701