PERFORMANCE MONITORING SYSTEM - DATASENSE

PERFORMANCE MONITORING SYSTEM - DATASENSE

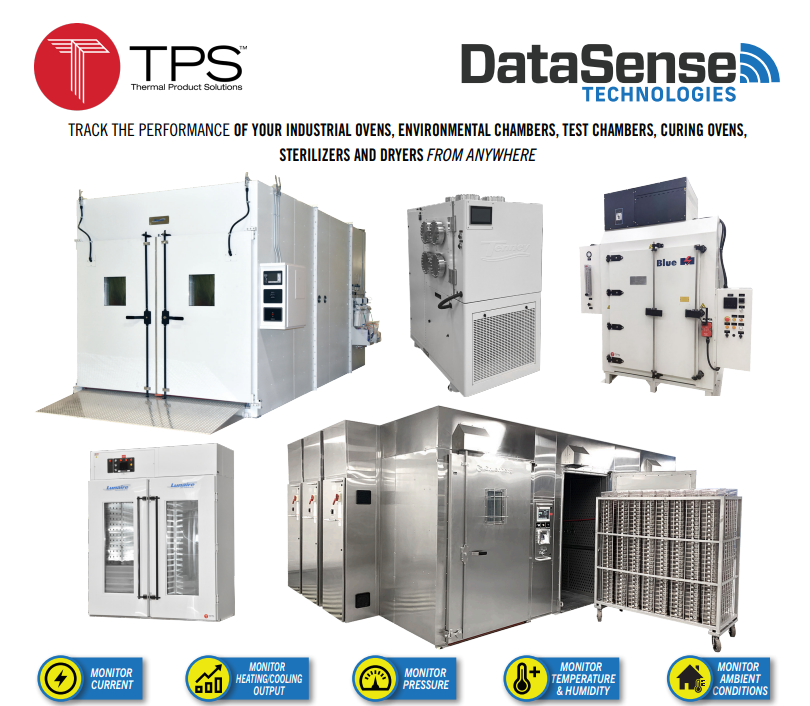

It’s no secret that industrial equipment deteriorates over time. Without a preventive maintenance program in place to keep the components of your system at peak performance, they may fail and lead to unplanned maintenance issues. Gruenberg’s partnership with DataSense Technologies allows you to track the performance of your environmental chamber with predictive maintenance sensors from anywhere.

It’s no secret that industrial equipment deteriorates over time. Without a preventive maintenance program in place to keep the components of your system at peak performance, they may fail and lead to unplanned maintenance issues. Gruenberg’s partnership with DataSense Technologies allows you to track the performance of your environmental chamber with predictive maintenance sensors from anywhere.

The DataSense Performance Monitoring System uses IoT (Internet of Things) technology to collect information from predictive maintenance sensors that track the performance and health of a variety of components in your environmental chamber. The information collected is stored locally on the MachinePulse for use. The data can be viewed via the web interface.

With the DataSense Performance Monitoring System, you can predict potential failure, reduce downtime, plan maintenance, diagnose remotely, and increase productivity and profitability. This system is available on new and most existing Gruenberg equipment.

Benefits of Performance Monitoring & Predictive Maintenance Sensors

Using an IoT gateway with MachinePulse, this system collects information from predictive maintenance sensors to track the performance and health of a variety of components and conditions in your environmental chamber. The gateway stores the information locally on the machine where it can be displayed in dashboards. Thresholds can be set around warning or alarm conditions to notify the operator.

- Predict Potential Failure - Predict component failures and take preventative measures prior to the failure occurring

- Reduce Downtime - Through continuous monitoring of the chamber operation, component failures can be diagnosed and corrected quickly

- Plan Maintenance - Preempts chamber failures so maintenance downtime can be scheduled

- Diagnose Remotely - Diagnose chamber problems quickly without waiting for a service technician to be scheduled

- Increase Productivity & Profitability - Minimize unplanned downtime to maximize the productivity of the chamber and increase profitability

DataSense Features

- Industrial grade predictive maintenance sensors are pre-wired and tested prior to shipment.

- Continuous monitoring – MachinePulse constantly monitors the system and notifies the operator when anomalies are detected.

- Dashboards are used to display the data being collected, as well as any alarm conditions – Accessible via an internet browser.

- Data storage - After being collected, the data points are accumulated and stored for analysis at any time via the dashboard.

What is Monitored?

The DataSense Technologies™ system continuously records important data points to make sure your equipment is running at peak performance levels. Types of sensors may include:

- Current

- PID Output

- Pressure

- Temperature

- Vibration

- Ambient Conditions

Installation Options

Talk to us about how to incorporate our system into your environmental chamber.

- Incorporated into new equipment

- Merged into existing equipment

- One, or many predictive maintenance sensors

Equipment Retrofits

Retrofit packages are available for Gruenberg and non-Gruenberg equipment.

System Security

- The DataSense system only collects data, and cannot affect the chamber operation, nor turn the chamber off or on. In the unlikely event of a failure of the DataSense system, the chamber will remain operational.